Scaling up craft to satisfy consumer demands

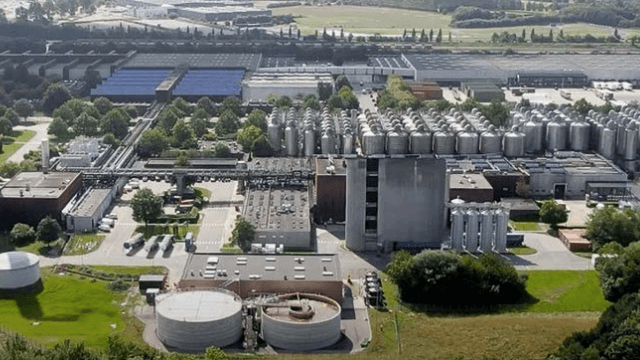

The brewery industry is shifting towards premium segments, requiring greater flexibility and consistency in production. With a focus on premium products that incorporate a wide variety of ingredients, brewers need technology that can adapt and maintain high quality. As consumer demand for unique brews rises, centrifugation technology becomes crucial for meeting these challenges.

DATE 2025-05-12The brewery industry is migrating into the premium segments, which means the production of products with a larger assortment of ingredients. To cater to this demand, technology-wise, centrifugation is providing brewers with flexibility and consistency in quality. These two factors are key for brewers to deliver the right product for the right market segment.

The trend of premium products is expected to grow over time, as consumers always seek something different. This growing demand places higher expectations on centrifugation technology. As such, the technology must evolve alongside the application to meet the rising challenges. The separator and its control systems must adapt to these changing needs.

Scaling craft beer production presents its own set of challenges. Unlike legacy products, craft beers are made in small batches with high specifications for the final product. These beers must be produced one after another in a very short amount of time. Thus, equipment needs to be flexible, able to make quick changes, and deliver consistent performance.

Alfa Laval’s centrifugation technology, with its unique Hermetic Design™, is the perfect solution for addressing these industry challenges. It provides brewers with the ability to produce premium-quality beer with zero oxygen pickup, all while minimizing utility consumption. This technology ensures that brewers can meet the high demands of the premium segment while maintaining efficiency and consistency.

Creación de un sistema de separación sostenible

Con el auge de los procesos sin kieselguhr en la industria cervecera, la demanda de sistemas de separación eficaces está aumentando. Escuche lo que un experto de Alfa Laval tiene que decir sobre cómo mejorar la eficiencia y minimizar el consumo de servicios públicos en la elaboración de cerveza.

Related products

Brew 750

- Hasta 1000 hl/h

- Hermetic Design™ significa un riesgo prácticamente nulo de captación de oxígeno

- Bajo consumo de energía

- Separador con sistema asociado completo

- Descarga de sólidos activada por turbidez

- Control de capacidad por turbidez de entrada

- Automatización Siemens o Allen Bradley