Enfriamiento del generador y de aceite de transformación

El éxito de la conversión de la energía térmica en electricidad requiere sistemas de islas de turbina seguros, fiables y eficientes. Al mismo tiempo, es fundamental garantizar la seguridad, la eficiencia de la conversión y el cumplimiento de la normativa, a la vez que se genera el máximo rendimiento. Alfa Laval tiene una amplia experiencia y una amplia gama de equipos y servicios fiables que ayudan a aumentar la seguridad, la eficiencia y el tiempo de actividad de la planta.

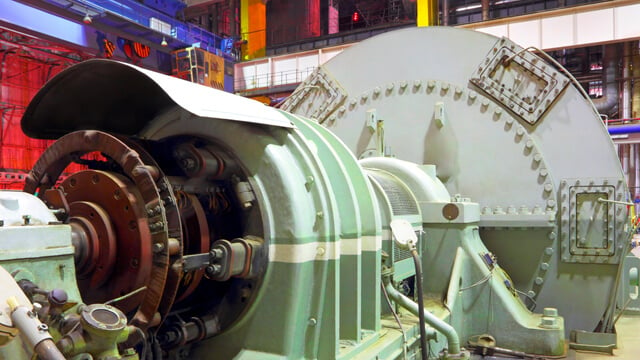

On the pulse of generator and transformer oil cooling

Converting mechanical energy into electrical power depends largely upon the generator. It is critical to prevent generator overheating and breakdown through efficient removal of the heat that results from conversion losses.

Our plate and frame solutions provide efficient cooling of the generator. The water transfers the heat from the generator to the intermediate closed loop cooling system. Alfa Laval has a broad portfolio of oil coolers that help maximize plant output.

Double wall industrial GPHE

The Alfa Laval double-wall gasketed plate heat exchanger provides added security to prevent cross-contamination of the oil with water. To maintain environmental safety, a double-wall plate heat exchanger is an excellent choice for direct cooling of transformer oil using cooling water from an open cooling system.

Air-cooled heat exchangers

For direct cooling when using a gasketed plate heat exchanger is not an option, Alfa Laval offers an extensive range of air cooled heat exchangers.

These Alfa Laval finned coil air heat exchangers are designed to optimize the exchange of thermal energy between air and a refrigerant or fluid. The ‘heart’ of our air heat exchangers is the finned coil built from a circuit of interconnected tube serpentines and fins, which increase the heat exchange surface area.

- AlfaSolar SD

- AlfaBlue series of heavy-duty air heat exchangers

- AlfaSolar SR

- Alfa-V