Válvula de alivio de presión SB

Para prevenir daños al tanque y ayudar a asegurar operaciones seguras, la válvula de alivio de presión SB de Alfa Laval protege un tanque presurizado durante un evento de sobrepresión. Está diseñado para procesos higiénicos en las industrias cervecera, láctea, alimentaria y de bebidas. La válvula puede integrarse con un sistema SCANDI BREW® para tanques.

Effective pressure relief

This pressure relief valve removes excess liquid that creates overpressure in the tank due to overfilling. When pressure in the tank exceeds a preset value, the pressure relief valve opens to vent fluid in the event of liquid overfilling, and closes when the tank pressure has returned to a safe level.

Easy-to-clean hygienic design

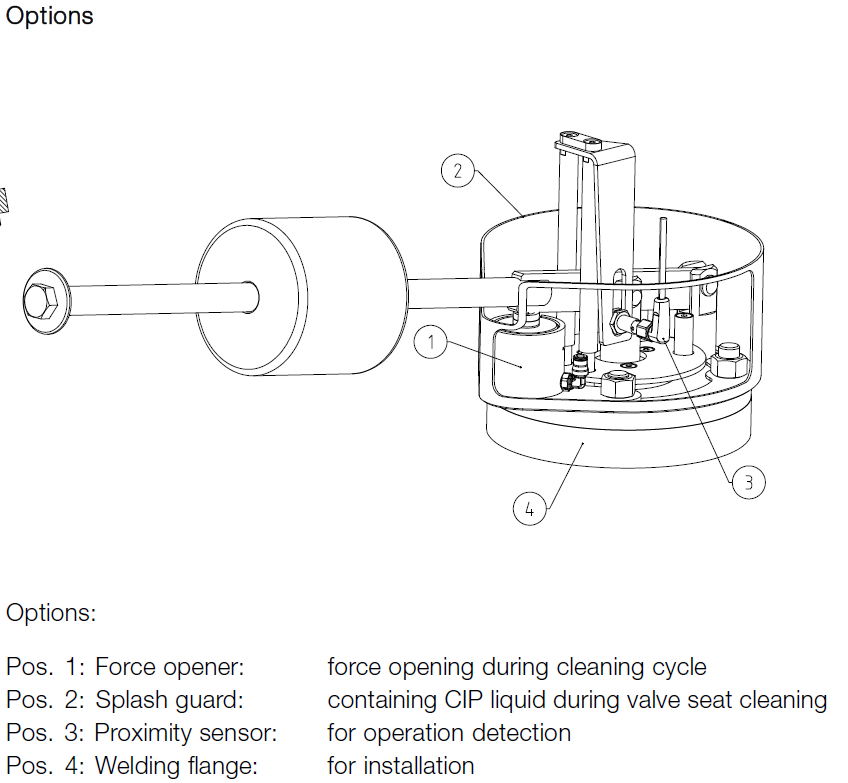

Few moving parts and smooth, crevice-free stainless steel surfaces make this valve easy to clean. When the valve is in closed position, it is cleaned as part of the routine Cleaning-in-Place (CIP) cycle. For thorough cleaning of the valve seat, an optional pneumatic force opener and a splash guard is available.

Product benefits

- Cost-effective, hygienic design

- Superior hygiene

- Customized to meet process requirements

- Easy to clean

Catálogo de productos

Cómo funciona

Construction

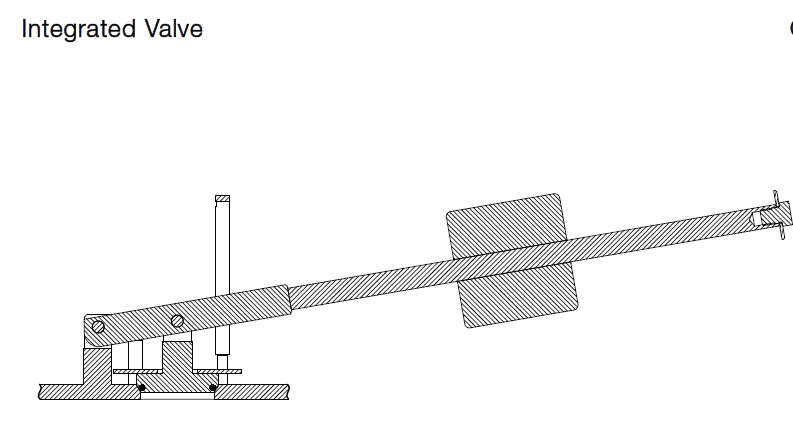

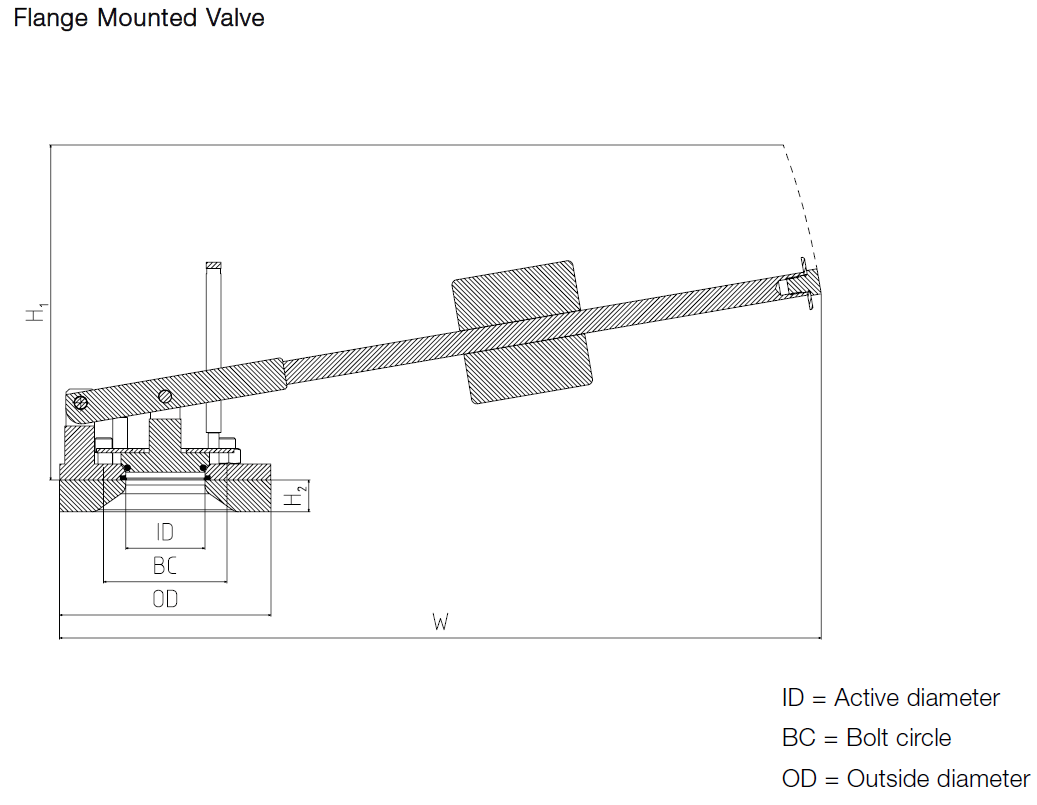

The Alfa Laval SB Pressure Relief Valve is a dead weight safety valve. It is compliant with PED 97/23/EC, EN 4126-1 and EN 764-7 and is available in two versions:

- Integrated with a SCANDI BREW® tank top system

- Mounted on its own counter flange

Operating principle

The pressure relief valve is delivered with the counterweight set and locked at the preset pressure that meets the customer’s requirements for opening pressure. When pressure in the tank exceeds the preset opening value, the valve relieves the excess pressure.

The preset opening pressure must be set at a value that is above the tank working pressure: 0.1 bar above for working pressures <1 bar, and 10% above for working pressures ≥ 1 bar. The valve should be seated horizontally. A maximum inclination of 10° is acceptable, but the lever arm must then point inward toward the centre of the cylindroconical tank top.

Cleaning-in-Place (CIP)

The valve is cleaned in closed position by the tank cleaning head. However, this does not include cleaning of the valve seat. To include the valve seat as an integral part of the cleaning cycle, an optional pneumatic force opener and optional splash guard are available.